The interface shear check between the girder and the diaphragm for girder continuity, as per IRC: 112-2020 (Limit State Design), ensures proper shear transfer at the connection. Below is a step-by-step procedure:

1. What is Interface Shear?

Interface shear is the shear force transmitted between different structural elements, in this case, between the main girder and the connecting diaphragm. This force must be accurately calculated and properly resisted to maintain structural integrity under various loads.

2. Design Forces

- Shear Force (V): The vertical shear force at the interface due to live loads, dead loads, and other effects.

- Moment (M): If eccentricity exists, additional shear may arise due to moment transfer.

3. Shear Stress Calculation

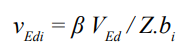

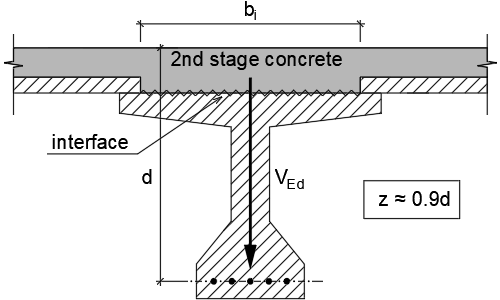

The nominal shear stress at the interface is calculated as:

Where:

- B = is the ratio of the longitudinal force in the new concrete and the total longitudinal force.

- VEd = Design shear force at the interface (from analysis)

- bi = Width of the interface (girder-diaphragm contact width)

- z = Lever arm ≈ 0.9d (where d is the effective depth)

(see also EN1992-1-1 Figure 6.8)

4. Shear Resistance Check

The design shear resistance vRd should be greater than vEd.

(A) As per IRC: 112-2020 (Clause 10.3.4)

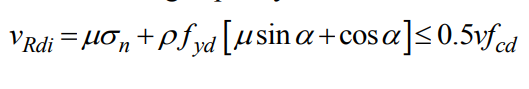

The shear resistance is given by:

Where:

- fcd = Design value of compressive strength of concrete

- μ = Friction coefficient (0.7 for rough interface)

- σn = Normal stress (if any compression exists)

- ρ = Reinforcement ratio =As/Ai

- fyd = Design Yield strength of reinforcement

- α = Angle of shear reinforcement (if provided)

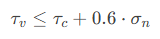

(B) As per IRC: 21-2000 (Working Stress Method)

The permissible shear stress is:

Where:

- τv = Calculated shear stress

- τc = Permissible shear stress (depends on concrete grade)

- σn = Normal stress (compression positive)

5. Reinforcement Requirements

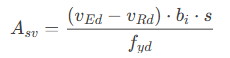

If vEd>vRd, provide shear reinforcement (dowels or links) crossing the interface:

Where:

- Asv = Area of shear reinforcement

- s = Spacing of reinforcement

6. Detailing Requirements

- The interface should be roughened (minimum 3 mm amplitude) for better shear transfer.

- Dowel bars or shear keys may be provided if necessary.

- Minimum reinforcement ρmin=0.15% of the contact area.

7. Importance of Girder Continuity

Ensuring adequate interface shear resistance allows the girder and diaphragm to behave monolithically, especially in continuous span bridges. This improves load distribution, reduces bending moments at mid-span, and enhances durability.

8. Best Practices

- Provide roughened surfaces at the interface for better frictional resistance.

- Use high-bond reinforcement across the interface.

- Always check limit states for both ultimate and serviceability conditions.

Conclusion

The design must satisfy:

vEd ≤ vRd

If not, increase concrete strength, provide shear reinforcement, or enhance interface roughness.

Find the attached Excel sheet for calculation, click here